To make cement waterproof, you can add waterproofing admixtures or apply a waterproofing sealant. These methods ensure durability and resistance to moisture.

Waterproofing cement is essential for structures exposed to wet conditions. Water damage can compromise the integrity of cement, leading to cracks and deterioration. Admixtures are chemical additives mixed with cement to enhance its water-resistant properties. Sealants, on the other hand, form a protective layer on the cement surface, preventing water penetration.

Proper waterproofing safeguards the longevity and strength of the construction. Selecting the right method depends on the specific project requirements and environmental conditions. With effective waterproofing, cement structures remain robust and resilient against moisture-related issues.

The Importance Of Waterproofing Cement

Waterproofing cement is crucial for any construction project. It ensures durability and longevity. Without waterproofing, cement structures can suffer severe damage over time.

Dangers Of Water Damage

Water can be very harmful to cement structures. Cracks, mold, and erosion are common issues caused by water. These problems can weaken the structure and make it unsafe.

- Cracks: Water can seep into small cracks and widen them.

- Mold: Damp conditions can lead to mold growth, which is unhealthy.

- Erosion: Water can wash away parts of the cement, causing erosion.

Benefits Of Waterproof Cement

Waterproof cement offers several advantages. It keeps structures strong and intact. This reduces maintenance costs and extends the life of the structure.

| Benefit | Description |

|---|---|

| Durability | Waterproof cement lasts longer and stays strong. |

| Cost-Effective | Reduces the need for frequent repairs and maintenance. |

| Healthier Environment | Prevents mold and mildew growth. |

Waterproof cement is crucial for any building project. It ensures safety, saves money, and promotes a healthier environment.

Credit: m.youtube.com

Cement Composition And Water Permeability

Understanding how cement interacts with water is crucial for making it waterproof. Cement is made up of various ingredients that impact its water permeability. Let’s dive into the basic ingredients of cement and how they interact with water.

Basic Ingredients Of Cement

Cement is composed of three primary ingredients:

- Limestone: A key ingredient that provides calcium.

- Clay: Adds silicon, aluminum, and iron.

- Gypsum: Controls the setting time of cement.

These ingredients are mixed and heated to form a product called clinker. Clinker is then ground into a fine powder, which is what we know as cement.

How Cement Interacts With Water

Cement’s interaction with water is a complex process. When water is added to cement, it starts a chemical reaction known as hydration. This reaction forms a gel-like substance that binds the particles together.

The hydration process creates small pores within the cement matrix. These pores can allow water to seep through, making the cement permeable. To make cement waterproof, we need to reduce these pores.

Here are some methods to make cement more waterproof:

- Use waterproofing additives: These chemicals fill the pores and reduce permeability.

- Apply waterproof coatings: These form a protective layer on the surface.

- Ensure proper mixing: A well-mixed cement has fewer pores.

By understanding the basic ingredients of cement and how it interacts with water, we can take steps to make it more waterproof. This ensures a longer lifespan and better performance of cement structures.

Methods Of Waterproofing Cement

Waterproofing cement is essential for durability. It protects from water damage and extends the lifespan of structures. There are various methods to make cement waterproof. Here, we explore three effective techniques: surface coatings, water repellent additives, and crystalline waterproofing.

Surface Coatings

Surface coatings create a protective layer on cement. These coatings block water from penetrating the surface. There are various types of coatings available:

- Acrylic Coatings: Easy to apply and flexible.

- Polyurethane Coatings: Highly durable and resistant to chemicals.

- Epoxy Coatings: Provide a strong, long-lasting barrier.

Apply coatings using brushes, rollers, or sprayers. Ensure the surface is clean and dry before application. Proper application ensures the coating adheres well and provides maximum protection.

Water Repellent Additives

Water repellent additives mix with cement during preparation. These additives enhance the cement’s water resistance. Common additives include:

- Silicone-Based Additives: Effective in repelling water.

- Powdered Additives: Easy to mix with cement.

- Liquid Additives: Provide even distribution in the mix.

Mix additives according to manufacturer instructions. Ensure a consistent blend for optimal results. These additives make the cement more resistant to water infiltration.

Crystalline Waterproofing

Crystalline waterproofing is a unique method. It involves adding chemicals to the cement mix. These chemicals form crystals within the cement. The crystals fill pores and cracks, blocking water pathways. Benefits of crystalline waterproofing include:

- Self-Sealing Properties: Crystals grow to seal new cracks over time.

- Permanent Solution: Crystals remain active for the structure’s lifespan.

- Easy Application: Can be applied as an admixture or surface treatment.

Apply crystalline products according to guidelines. This ensures effective waterproofing and long-term protection for the cement.

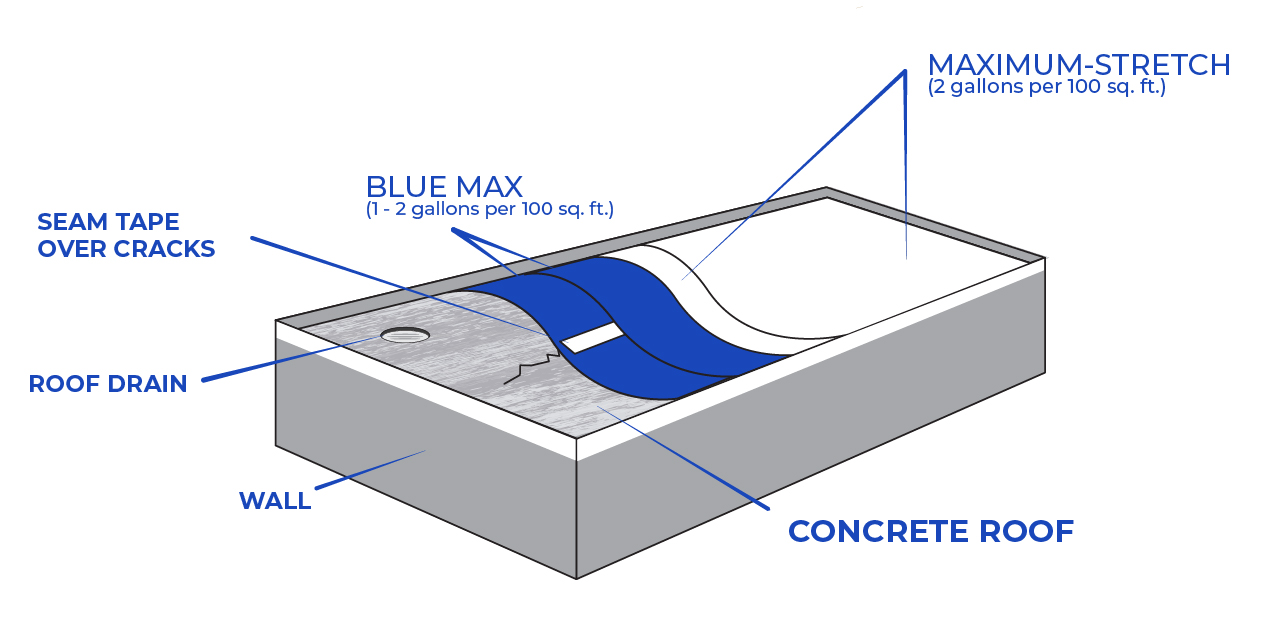

Waterproof Coatings: Types And Application

Using waterproof coatings is an effective way to protect cement from water damage. Different types of coatings offer unique benefits. This section explores three popular types of waterproof coatings: Acrylic, Epoxy, and Polyurethane. Learn how to apply each one to keep your cement structures safe and dry.

Acrylic Coatings

Acrylic coatings are widely used for waterproofing cement. They are easy to apply and dry quickly. Acrylic coatings form a flexible film over the cement surface. This film is resistant to water and UV rays.

Follow these steps to apply acrylic coatings:

- Clean the cement surface thoroughly.

- Ensure the surface is dry and free of dust.

- Apply a primer to the cement surface.

- Use a brush or roller to apply the acrylic coating.

- Allow the first coat to dry completely.

- Apply a second coat for better protection.

Epoxy Coatings

Epoxy coatings provide a strong and durable waterproof layer. They are perfect for areas with heavy foot traffic. Epoxy coatings are also resistant to chemicals and stains.

Steps to apply epoxy coatings:

- Clean the cement surface with a degreaser.

- Repair any cracks or holes in the cement.

- Mix the epoxy resin and hardener according to instructions.

- Apply the mixture using a brush or roller.

- Allow the first coat to cure as per manufacturer’s instructions.

- Apply a second coat if needed for extra durability.

Polyurethane Coatings

Polyurethane coatings offer excellent flexibility and water resistance. They are ideal for surfaces exposed to weather changes. These coatings also resist abrasion and chemicals.

To apply polyurethane coatings:

- Start by cleaning the cement surface.

- Make sure the surface is dry and smooth.

- Apply a primer if recommended by the manufacturer.

- Use a brush or roller to spread the polyurethane coating evenly.

- Let the first coat dry completely before applying a second coat.

- Apply a second coat for enhanced protection.

Choosing the right waterproof coating and applying it correctly ensures your cement stays protected. Follow these steps to achieve a waterproof cement surface.

Integral Waterproofing: Mixing And Curing

Creating waterproof cement involves more than just mixing ingredients. The process includes choosing the right additives, proper mixing techniques, and curing for optimal strength. This section will guide you through these crucial steps.

Choosing The Right Additives

Using integral waterproofing additives is key for making cement waterproof. These additives mix directly into the cement. They help prevent water from penetrating the concrete. Popular additives include:

- Silica-based products

- Crystalline admixtures

- Hydrophobic agents

Each additive has its own benefits. Silica-based products fill pores in the concrete. Crystalline admixtures form crystals to block water paths. Hydrophobic agents repel water.

Proper Mixing Techniques

Proper mixing ensures the additives blend well with the cement. Follow these steps:

- Measure the cement and additives carefully.

- Mix dry ingredients first for even distribution.

- Add water gradually while mixing.

- Use a mechanical mixer for best results.

Consistent mixing is important. It helps the additives spread evenly, ensuring the cement is waterproof.

Curing For Optimal Strength

Curing is the process of maintaining moisture in the cement after mixing. Proper curing increases strength and durability. Follow these steps for effective curing:

- Keep the cement surface moist.

- Cover the cement with a plastic sheet.

- Spray water on the surface regularly.

- Continue curing for at least 7 days.

Moisture is essential during curing. It helps the cement achieve maximum strength and ensures the waterproofing additives work effectively.

By following these steps, you can create waterproof cement that lasts longer and performs better.

Advanced Waterproofing: Nanotechnology In Cement

Advanced waterproofing solutions for cement have revolutionized the construction industry. Nanotechnology, a cutting-edge field, brings incredible waterproofing capabilities to cement. This technology ensures durability and longevity of structures.

Nano-coatings

Nano-coatings provide a thin, protective layer on the cement surface. These coatings consist of tiny particles that are invisible to the naked eye. They create a barrier, preventing water from penetrating the cement.

The application process for nano-coatings is simple. Builders can spray or brush these coatings onto the cement. This method ensures even coverage and effective protection.

Nano-coatings are highly durable. They withstand harsh weather conditions and resist wear and tear.

Silica Nanoparticles

Silica nanoparticles are another innovative solution. These tiny particles mix with cement, enhancing its properties. They fill in the microscopic pores within the cement, making it denser and more waterproof.

Using silica nanoparticles in cement offers multiple benefits. They increase the strength of the cement and reduce its permeability.

Builders mix silica nanoparticles with cement during the production process. This ensures a uniform distribution of the particles.

Benefits Of Nanotechnology

The benefits of nanotechnology in cement are numerous. Here are some key advantages:

- Enhanced waterproofing

- Increased durability

- Improved strength

- Resistance to harsh weather

- Reduced maintenance costs

These benefits make nanotechnology an ideal choice for modern construction projects.

| Feature | Benefit |

|---|---|

| Nano-coatings | Provide a protective barrier on cement |

| Silica Nanoparticles | Enhance cement strength and density |

| Durability | Resist harsh weather and wear |

Diy Waterproofing Projects

DIY waterproofing projects can save you money and enhance your home’s durability. Waterproofing cement is a great way to protect surfaces from water damage. Follow these steps to make your cement surfaces waterproof. This guide is simple and easy to follow.

Preparing Your Workspace

Preparation is key to a successful waterproofing project. Ensure your workspace is clean and organized before starting.

- Clear the area of any debris.

- Clean the cement surface with a brush and soapy water.

- Let the surface dry completely.

- Gather all necessary tools and materials.

Having everything ready will make the process smooth and efficient.

Step-by-step Waterproofing Process

Follow these simple steps to waterproof your cement effectively:

- Mix the Waterproofing Agent: Combine the waterproofing agent with the cement according to the manufacturer’s instructions.

- Apply the First Coat: Use a brush or roller to apply the first coat of the mixture. Ensure even coverage.

- Let It Dry: Allow the first coat to dry completely. This may take a few hours.

- Apply the Second Coat: Apply a second coat for added protection. Again, ensure even coverage.

- Final Drying: Let the second coat dry thoroughly before using the surface.

Tips for Best Results:

- Work in a well-ventilated area.

- Wear protective gear to avoid skin contact with chemicals.

- Follow the product instructions carefully.

By following these steps, you can ensure your cement surfaces are waterproof and durable. Enjoy a longer-lasting, water-resistant home.

Credit: amesresearch.com

Professional Waterproofing Services

Ensuring your cement is waterproof can be a challenging task. While DIY methods are popular, professional waterproofing services offer expertise and reliability. Professionals use advanced techniques and materials, guaranteeing lasting protection for your cement structures.

When To Hire A Professional

Hire a professional if you notice water seepage or damp walls. Water stains or mold growth are signs of water damage. Professionals can address these issues effectively.

Large areas or complex structures require expert handling. Professionals have the tools and experience for such tasks. For long-term solutions, professional services are the best choice.

What To Look For In A Service Provider

When choosing a service provider, consider their experience and reputation. Look for reviews and testimonials from previous clients.

Ensure they use high-quality materials and modern techniques. This ensures the waterproofing will last.

A good provider offers a comprehensive inspection before starting the work. They should also provide a detailed quote and timeline.

Check if they offer a warranty for their services. A warranty indicates confidence in their work.

| Criteria | Importance |

|---|---|

| Experience | High |

| Reputation | High |

| Materials Used | High |

| Inspection and Quote | Medium |

| Warranty | High |

Choosing the right professional ensures your cement is protected from water damage. This keeps your structures strong and durable for years.

Maintenance Of Waterproofed Cement Surfaces

Maintaining waterproofed cement surfaces is essential to ensure their longevity and effectiveness. Regular upkeep can prevent water damage and keep the surface in excellent condition. This section will cover the key steps to maintain your waterproofed cement surfaces.

Routine Checks

Conducting routine checks is crucial for spotting potential issues early. Here’s a simple checklist:

- Inspect the surface for cracks or chips.

- Check for water stains or discoloration.

- Ensure that drainage systems are functioning properly.

- Look for signs of mold or mildew.

Regular inspections can help identify problems before they become serious. Aim to perform these checks at least once every three months.

Repairing Damages

Repairing damages promptly is vital to maintain the integrity of waterproofed cement surfaces. Follow these steps to address common issues:

- Clean the damaged area thoroughly to remove dirt and debris.

- Fill any cracks or chips with a suitable cement filler.

- Allow the filler to dry completely as per manufacturer instructions.

- Apply a fresh coat of waterproof sealant to the repaired area.

Using high-quality materials for repairs ensures durability and effective waterproofing. Always follow the manufacturer’s guidelines for the best results.

Environmental And Health Considerations

Creating waterproof cement can have significant environmental and health impacts. It’s essential to choose methods and materials that are safe for both the planet and people. This section explores eco-friendly options and safety tips for DIY projects.

Eco-friendly Waterproofing Options

Using eco-friendly materials helps reduce the environmental footprint. Here are some options:

- Natural Sealants: These are made from plants and other natural sources. They are biodegradable and non-toxic.

- Water-Based Sealants: These contain fewer chemicals compared to solvent-based options. They are less harmful to both people and the environment.

- Recycled Materials: Some waterproofing materials use recycled content. This reduces waste and conserves resources.

Choosing eco-friendly options helps protect the environment. It also ensures a safer space for everyone.

Safety Tips For Diy Projects

Safety should always be a priority in DIY projects. Here are some important tips:

- Wear Protective Gear: Always use gloves, masks, and safety glasses. This protects your skin, lungs, and eyes from harmful substances.

- Work in Ventilated Areas: Ensure you have good airflow. This reduces exposure to fumes and dust.

- Read Labels: Always read the labels on products. Follow the instructions carefully to avoid accidents.

- Store Materials Safely: Keep all materials out of reach of children and pets. Store them in a cool, dry place.

Following these tips will help you stay safe. It ensures a successful and accident-free project.

Credit: www.ecoformeurope.com

Frequently Asked Questions

Can You Seal Cement To Be Waterproof?

Yes, you can seal cement to make it waterproof. Use a high-quality concrete sealer to protect it. Applying the sealer correctly ensures durability and water resistance. Proper maintenance can extend the seal’s effectiveness.

Can Cement Be Waterproof?

Yes, cement can be made waterproof. Adding waterproofing agents or using special waterproof cement mixes can achieve this.

Is There An Additive For Concrete To Make It Waterproof?

Yes, concrete waterproofing additives are available. These include integral waterproofing agents, crystalline admixtures, and silicone-based sealers. They enhance durability and moisture resistance.

What Is The Best Cement Mix For Waterproofing?

The best cement mix for waterproofing is a blend of Portland cement, sand, and a waterproofing agent. Use a 1:2 ratio of cement to sand, and add the recommended amount of waterproofing additive. This mix ensures strong, durable, and water-resistant concrete.

Conclusion

Ensuring your cement is waterproof can extend the lifespan of your structures. By following the outlined methods, you can protect your investment from water damage. Remember to use quality materials and adhere to best practices for optimal results. Waterproofing cement is a crucial step for durable and resilient construction.