Concrete forms the backbone of modern construction. From high-rises to homes, it’s relied upon for its strength and durability. But even the smallest mistake in concrete work can lead to structural failure, costly repairs, or complete rebuilds.

Whether you are a homeowner, a construction professional, a business owner, or a civil engineering student, this guide will help you understand the most common concrete pitfalls and how to avoid them.

Why Avoiding Concrete Mistakes Is Critical to Construction Success

Concrete is the backbone of modern construction, providing durability and strength to buildings, bridges, and infrastructure. However, mistakes in its handling, mixing, pouring, or curing can lead to severe structural and financial repercussions.

1. Weak Foundations and Unstable Structures

A building is only as strong as its foundation, and concrete errors at this stage can compromise the entire structure.

- Poor Mix Design: Using incorrect water-cement ratios or insufficient reinforcement can weaken the concrete, leading to settling or shifting over time.

- Improper Compaction: If air pockets or voids remain due to inadequate vibration during pouring, the concrete loses density, reducing load-bearing capacity.

- Example: The Leaning Tower of Pisa is a famous case of foundation failure—its uneven settling was caused by unstable soil, but similar issues can arise from poorly executed concrete work.

2. Cracking, Spalling, and Surface Damage

Concrete is prone to deterioration if not properly mixed, placed, or cured.

- Plastic Shrinkage Cracks: Occur when water evaporates too quickly from fresh concrete, often due to hot weather or lack of moisture control.

- Spalling: Caused by corrosion of embedded steel rebar, which expands and breaks the concrete apart—common in structures exposed to de-icing salts or marine environments.

- Example: Many aging bridges in cold climates suffer from spalling due to repeated freeze-thaw cycles and salt exposure, requiring costly repairs.

3. Higher Long-Term Maintenance Costs

Taking shortcuts during construction often results in exponential expenses later on.

- Premature Repairs: Poor-quality concrete may need patching or replacement within years instead of decades.

- Water Infiltration: Cracks allow moisture penetration, leading to mold, rust, and further degradation.

- Case Study: The Sydney Opera House experienced concrete degradation due to alkali-silica reaction (ASR), requiring extensive restoration decades earlier than anticipated.

4. Missed Project Deadlines

Concrete mistakes can cause delays, disrupting entire project timelines.

- Slow Curing in Cold Weather: If proper insulation or heating isn’t used, concrete takes longer to reach strength, delaying subsequent construction phases.

- Rejection of Defective Work: Structural flaws may require demolition and re-pouring, pushing back completion dates.

- Example: The Berlin Brandenburg Airport faced years of delays partly due to concrete work defects, including improper fireproofing and cracking.

5. Legal and Safety Issues

Faulty concrete can lead to catastrophic failures, lawsuits, and regulatory penalties.

- Collapse Risks: Weak concrete in high-rise buildings or bridges can result in partial or total structural failure, endangering lives.

- Code Violations: Non-compliance with building standards can lead to fines, forced demolitions, or denied occupancy permits.

- Case Study: The 2018 Florida Pedestrian Bridge Collapse, which killed six people, was linked to design and concrete placement errors, leading to legal repercussions for the firms involved.

The Importance of Proper Concrete Practices

Understanding and avoiding these mistakes is not just about cost savings—it’s about ensuring safety, longevity, and efficiency in construction. Best practices include

- Precision in Mix Design: Tailoring concrete composition to environmental and structural demands.

- Proper Curing Techniques: Maintaining moisture and temperature for optimal strength development.

- Quality Control Testing: Regular slump tests, compressive strength checks, and rebar inspections.

- Adherence to Standards: Follow Bangladesh National Building Code (BNBC) guidelines to ensure safety and durability in construction.

By prioritizing these measures, engineers and contractors can deliver structures that endure over time, minimizing risks, maximizing durability, and ensuring public safety.

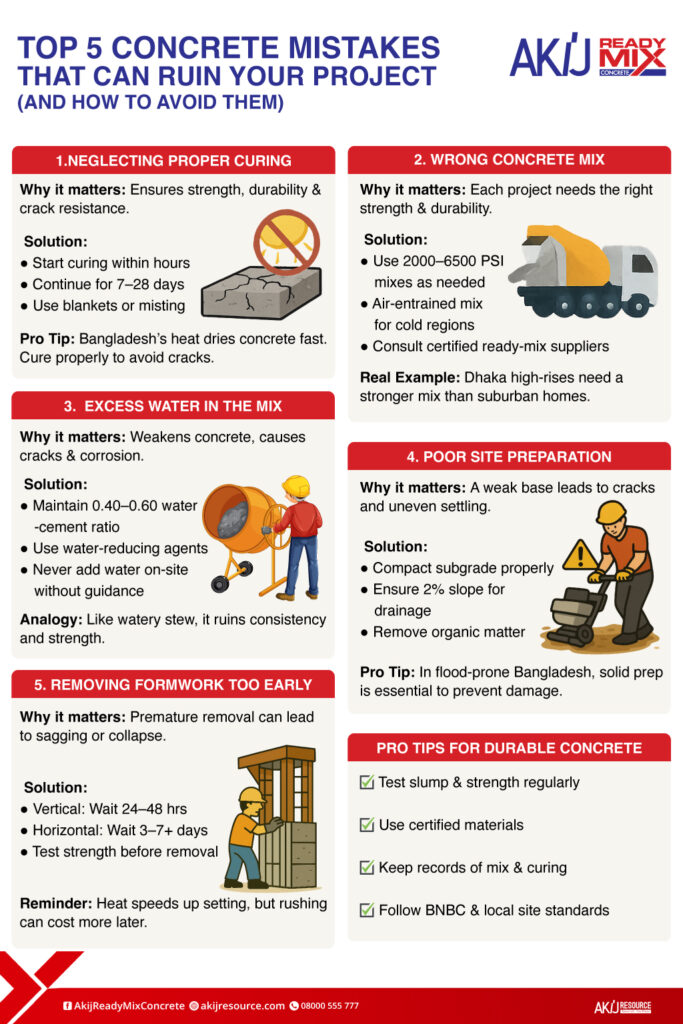

1. Neglecting Proper Curing: A Shortcut That Compromises Strength

Why It’s a Problem:

Curing is one of the most overlooked yet critical steps in concrete construction. Many contractors or site workers often skip or shorten this phase, thinking the job is done once the concrete has hardened.

Consequences of Poor Curing:

- Surface Cracks and Shrinkage

- Reduced Resistance to Weather and Chemicals

- Loss of Compressive Strength (up to 50%)

- Dusting and Scaling

How to Avoid It:

- Maintain moisture for at least 7 days (extend to 14–28 days for structural work).

- Use curing compounds for large projects.

- Prevent rapid moisture loss with sunshades or misting in hot climates.

- Monitor temperature in cold weather with insulating blankets.

Pro Tip: Start curing within a few hours after pouring for best results.

2. Choosing the Wrong Concrete Mix Design: One Size Doesn’t Fit All

Why It’s a Problem:

Using a generic mix can lead to:

- Weak or brittle concrete

- Inadequate durability under load

- Susceptibility to weathering/chemical damage

How to Avoid It:

- Determine the required compressive strength (3000–5000 PSI).

- Use air-entrained concrete for freeze-thaw conditions.

- Add admixtures (retarders, plasticizers) as needed.

- Work with certified ready-mix suppliers for custom formulations.

Real-World Example: Parking garage slabs need 5000 PSI, while interior flooring may only require 3000 PSI.

3. Incorrect Water-to-Cement Ratio: When More Isn’t Better

Why It’s a Problem:

- Reduced strength (up to 10% per extra liter of water)

- Increased shrinkage & cracking

- Higher porosity & corrosion risk

How to Avoid It:

- Maintain an optimal W/C ratio (0.40–0.60).

- Use water-reducing admixtures for workability.

- Never add water on-site without supervision.

Analogy: Adding water to concrete is like diluting soup—it ruins the balance.

4. Inadequate Site Preparation: Weak Ground, Weak Structure

Why It’s a Problem:

- Uneven settling & cracks

- Poor drainage & water damage

How to Avoid It:

- Remove organic materials and compact the subgrade.

- Add a gravel/crushed stone base.

- Ensure proper grading (2% slope minimum).

- Check for underground utilities & water tables.

Case Study: A Dhaka housing project failed due to poor compaction, while a properly prepared site remained stable.

5. Removing Formwork Too Early: Risking Structural Collapse

Why It’s a Problem:

- Sagging or collapse

- Surface defects

How to Avoid It:

- Follow minimum removal times:

- Vertical elements (24–48 hrs)

- Horizontal elements (3–7+ days)

- Test compressive strength before removal.

- Adjust for cold weather delays.

Final Reminder: Rushing formwork removal can lead to costly rework.

Common Challenges & Solutions in Concrete Projects

| Challenge | Solution |

| Inconsistent curing | Use wet coverings, curing compounds |

| Mix variability | Work with certified suppliers |

| Weather delays | Plan for insulation/heating |

| Lack of skilled labor | Provide training & SOPs |

Best Practices for Concrete Success

✔ Perform slump tests on-site

✔ Store materials dry & uncontaminated

✔ Document mix design, curing, tests

✔ Plan for weather extremes

✔ Reinforce based on structural load

Innovations in Concrete Technology

- Green concrete (low-carbon materials)

- Smart concrete (embedded sensors)

- Self-healing concrete (bacteria-based repair)

- 3D-printed concrete (automated construction)

Conclusion: Build Stronger by Avoiding These Mistakes

Concrete mistakes can be costly, but by following best practices—proper curing, mix design, W/C ratio, site prep, and formwork timing—you ensure long-lasting, safe, and durable structures.