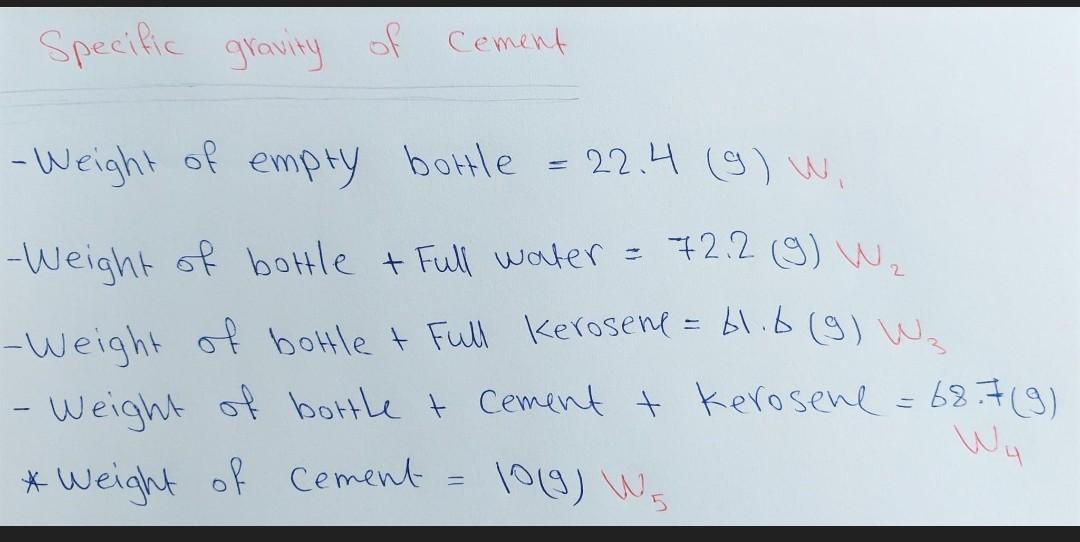

To determine the specific gravity of cement, use a Le Chatelier flask and kerosene. Measure the volume change after adding cement.

Specific gravity is crucial for understanding cement quality and consistency. This measurement helps in mix design calculations and quality control. It influences the workability and strength of the final concrete mix. Accurate determination ensures the cement meets industry standards. Typically, the specific gravity of cement ranges between 3. 1 to 3. 16.

A deviation from this range can indicate issues like excess moisture or impurities. Knowing the specific gravity helps in proportioning the mix accurately. This ensures a durable and strong concrete structure. Properly measured specific gravity is essential for any construction project, ensuring safety and longevity.

Introduction To Specific Gravity And Cement

Specific gravity is a key property of cement. It helps us understand the density of cement compared to water. Knowing the specific gravity helps in the mix design and quality control of concrete. Let’s dive into the importance and basics of cement composition.

Importance Of Specific Gravity In Cement

The specific gravity of cement affects the strength and durability of concrete. It helps in calculating the mix proportions accurately. This ensures that the concrete mix is efficient and cost-effective.

High specific gravity indicates denser cement particles. This results in stronger concrete. On the other hand, low specific gravity might indicate the presence of voids or impurities. This can weaken the concrete.

Here’s a simple table to show the significance of specific gravity:

| Property | Effect on Concrete |

|---|---|

| High Specific Gravity | Stronger, denser concrete |

| Low Specific Gravity | Weaker, porous concrete |

Fundamentals Of Cement Composition

Cement is made from limestone, clay, and other materials. These materials are heated to form a clinker. The clinker is then ground to make cement powder.

The main components of cement are calcium silicates, aluminates, and ferrites. These components react with water to form a hard mass. The specific gravity of cement depends on these components.

Here’s an ordered list of the main steps in cement production:

- Extraction of raw materials

- Mixing and heating to form clinker

- Grinding clinker to make cement

In summary, understanding the specific gravity and composition of cement is crucial. It ensures the quality and durability of concrete structures.

Credit: www.chegg.com

Essentials Of Specific Gravity

Understanding the specific gravity of cement is crucial. It helps in determining the quality and performance of cement. Specific gravity measures the density of cement compared to water. This value influences the strength and stability of concrete structures.

Defining Specific Gravity

Specific gravity is a ratio. It compares the weight of a substance to the weight of an equal volume of water. For cement, this value typically ranges between 3.1 and 3.2. This indicates cement is heavier than water.

Role In Cement Quality And Performance

The specific gravity of cement affects its quality and performance. Higher specific gravity means denser and stronger cement. It ensures better strength and durability in concrete structures.

Specific gravity also impacts the mixing process. Knowing this value helps in accurate measurement of water and aggregates. This ensures the right consistency of the concrete mix.

| Specific Gravity | Impact on Cement |

|---|---|

| 3.1 – 3.2 | Higher strength and durability |

| Below 3.1 | Potential lower quality |

To summarize, understanding specific gravity is essential. It directly influences the quality and performance of cement. Accurate measurements ensure the best results for concrete structures.

Standard Test Methods

Determining the specific gravity of cement is crucial for quality control in construction. Several methods are available, each with its own procedure and accuracy. This section covers two standard test methods: Le Chatelier’s Flask Method and the Pycnometer Method for Specific Gravity.

Le Chatelier’s Flask Method

The Le Chatelier’s Flask Method is a common technique. It uses a special flask with a narrow neck. This flask is calibrated to measure the displacement of liquid.

Here are the steps involved:

- Fill the flask with kerosene up to a marked level.

- Record the initial volume of kerosene.

- Add a known weight of cement to the flask.

- Record the new volume of kerosene.

- Calculate the specific gravity using the formula: Specific Gravity = Weight of Cement / (Final Volume – Initial Volume)

This method is accurate but requires careful measurement.

Pycnometer Method For Specific Gravity

The Pycnometer Method is another reliable technique. A pycnometer is a glass container with a close-fitting stopper. It has a capillary tube through which excess liquid can escape.

Follow these steps for the Pycnometer Method:

- Weigh the empty pycnometer.

- Fill it with water and weigh it again.

- Empty the pycnometer and fill it with a known weight of cement.

- Add water to fill the pycnometer and weigh it.

- Calculate the specific gravity using the formula: Specific Gravity = (Weight of Cement) / (Weight of Displaced Water)

This method is simple and quick, making it popular in many laboratories.

| Method | Accuracy | Equipment Needed |

|---|---|---|

| Le Chatelier’s Flask Method | High | Le Chatelier Flask, Kerosene |

| Pycnometer Method | Medium | Pycnometer, Water |

Step-by-step Procedure

Determining the specific gravity of cement is crucial for quality control. This process involves precise steps to ensure accurate results. Below, we break down the procedure into easy-to-follow steps.

Preparation Of Materials

Before starting the test, gather all necessary materials. You will need:

- Pycnometer: A standard container for measuring specific gravity.

- Cement sample: Ensure it is dry and free from moisture.

- Balance: A precise weighing scale.

- Distilled water: To fill the pycnometer.

- Glass rod: For stirring.

- Thermometer: To measure the temperature.

Ensure all materials are clean and dry before use. This helps in getting accurate measurements.

Execution Of The Specific Gravity Test

- Weigh the empty pycnometer: Record the weight as

W1. - Fill the pycnometer with cement: Weigh again and note this weight as

W2. - Add distilled water: Fill the pycnometer with distilled water and stir with the glass rod to remove air bubbles.

- Weigh the filled pycnometer: Record this combined weight as

W3. - Empty and refill with water: Clean the pycnometer, fill it with water only, and weigh. Note this as

W4. - Calculate specific gravity: Use the formula:

Specific Gravity = (W2 - W1) / [(W4 - W1) - (W3 - W2)]

Ensure all measurements are accurate and consistent. This will give you the correct specific gravity of the cement.

Calculating Specific Gravity

Understanding how to calculate the specific gravity of cement is crucial for construction and quality control. This vital property ensures that the cement meets the necessary standards and specifications. Let’s dive into the process of calculating the specific gravity.

Formula And Computation

To determine the specific gravity of cement, we use the formula:

Specific Gravity (SG) = (Weight of Cement / Weight of Equal Volume of Water)Follow these steps to compute the specific gravity:

- Weigh an empty container (W1).

- Fill the container with cement and weigh it (W2).

- Fill the container with water and weigh it (W3).

Now, use the formula:

SG = (W2 - W1) / (W3 - W1)Ensure all measurements are accurate for precise results.

Interpreting The Results

Understanding the results is essential for quality control. The specific gravity of cement usually ranges between 3.1 and 3.16. If the value falls outside this range, it could indicate impurities or issues with the cement.

Compare the calculated specific gravity with standard values:

| Specific Gravity Value | Interpretation |

|---|---|

| 3.1 – 3.16 | Normal, good quality cement |

| < 3.1 | Possible impurities or lower quality |

| > 3.16 | Possible contamination or higher density materials |

Regular testing ensures the cement meets the required standards. Quality control is key in construction projects.

Factors Affecting Cement’s Specific Gravity

Understanding the specific gravity of cement helps in calculating the mix ratio for concrete. Several factors can influence this important property. Here, we explore two major factors: cement particle size and moisture content.

Impact Of Cement Particle Size

The size of cement particles can greatly influence its specific gravity. Smaller particles have a higher surface area compared to larger ones. This can lead to different packing densities.

Fine particles tend to pack more tightly, resulting in a higher specific gravity. Coarser particles, on the other hand, may not pack as efficiently, leading to a lower specific gravity.

| Particle Size | Specific Gravity |

|---|---|

| Fine | Higher |

| Coarse | Lower |

Moisture Content And Its Effects

Moisture content also plays a crucial role in determining cement’s specific gravity. Water presence can alter the weight and volume of cement.

When cement absorbs water, it becomes heavier, increasing its specific gravity. Conversely, dry cement has a lower specific gravity due to the absence of water.

- Wet Cement: Higher specific gravity

- Dry Cement: Lower specific gravity

Practical Applications

Determining the specific gravity of cement is essential in various construction activities. It helps ensure the quality and consistency of the cement used in building projects. This knowledge has several practical applications, especially in mix design and quality control.

Mix Design Considerations

Specific gravity affects the mix design of concrete. It helps calculate the proportions of cement, water, and aggregates. This ensures the concrete mix achieves the desired strength and durability.

Using cement with the correct specific gravity ensures the concrete mix is neither too dense nor too light. This balance is crucial for structural stability.

A table can help illustrate the impact of specific gravity on mix design:

| Specific Gravity | Water-Cement Ratio | Mix Proportions |

|---|---|---|

| 3.15 | 0.45 | 1:2:4 |

| 3.10 | 0.50 | 1:2.5:4.5 |

| 3.20 | 0.40 | 1:1.75:3.5 |

Quality Control In Construction Projects

Checking the specific gravity of cement is a quality control measure. It ensures the cement used meets the required standards.

Regular testing helps detect any deviations in cement quality. This prevents potential structural issues in the future.

Steps for quality control include:

- Sampling cement from different batches.

- Testing specific gravity using standard equipment.

- Comparing results with standard values.

- Documenting and addressing any discrepancies.

By following these steps, construction projects maintain high standards and ensure safety and durability.

Troubleshooting Common Issues

Determining the specific gravity of cement can sometimes present challenges. It is important to address these issues to ensure accurate results. Troubleshooting common problems can help in achieving consistent and reliable measurements.

Dealing With Inconsistent Results

Inconsistent results can be frustrating. Understanding the potential causes can help resolve these issues. Common reasons include:

- Improper calibration of equipment: Ensure all equipment is properly calibrated before use.

- Temperature variations: Conduct tests in a controlled environment to avoid temperature fluctuations.

- Inaccurate measurements of materials: Use precise measuring tools for cement and water.

Addressing these factors can significantly improve the consistency of your results.

Tips For Accurate Measurements

Accurate measurements are crucial for determining the specific gravity of cement. Here are some tips:

- Use a clean, dry pycnometer: Ensure the pycnometer is free from any residue.

- Maintain a constant temperature: Perform the test at a consistent temperature for accurate readings.

- Avoid air bubbles: Carefully add cement to the pycnometer to prevent air entrapment.

- Record precise volumes: Use a graduated cylinder for accurate volume measurements.

Following these tips can help achieve more accurate and reliable measurements.

Safety And Precautions

Determining the specific gravity of cement requires precise procedures. It’s vital to follow safety guidelines to ensure accurate results and prevent accidents. This section outlines the necessary precautions.

Handling And Disposal Of Materials

Always wear protective gear such as gloves, goggles, and masks. Cement dust can irritate skin and eyes.

- Store cement in a dry, cool place.

- Avoid inhaling dust by wearing a mask.

- Clean spills immediately to prevent slipping hazards.

- Dispose of cement waste in accordance with local regulations.

Use a vacuum cleaner instead of sweeping to avoid dust clouds. Never dispose of cement in regular trash bins.

Ensuring Accurate And Safe Testing

Calibration of equipment is crucial for accurate results. Check your equipment before each test.

- Measure the cement with calibrated scales.

- Use clean, dry containers for mixing and testing.

- Avoid contamination by cleaning tools thoroughly.

Follow the standard procedures for mixing and measuring. This ensures consistency and accuracy.

Always work in a well-ventilated area to avoid inhaling harmful fumes or dust.

Keep a first aid kit nearby in case of accidents.

In the table below, you can find the essential safety gear and their purposes:

| Safety Gear | Purpose |

|---|---|

| Gloves | Protects hands from cement burns |

| Goggles | Shields eyes from dust and splashes |

| Mask | Prevents inhalation of dust particles |

| Apron | Protects clothing and skin |

Following these safety and precautionary measures ensures a safe working environment and accurate test results.

Conclusion And Best Practices

Determining the specific gravity of cement is crucial for construction projects. It helps ensure the quality and consistency of the cement used. This section outlines the key takeaways and best practices for maintaining high standards in future tests.

Summarizing Key Takeaways

- Accurate Measurement: Use precise tools for measuring the weight and volume of cement.

- Calibrated Equipment: Ensure all equipment is calibrated before use.

- Consistent Procedures: Follow a standard procedure to avoid errors.

- Temperature Control: Perform tests at a consistent temperature to ensure accuracy.

- Record Keeping: Document all test results for future reference.

Maintaining Standards In Future Tests

Maintaining high standards in future tests is essential for consistent results. Here are some best practices to follow:

- Regular Calibration: Calibrate your equipment regularly to maintain accuracy.

- Standardized Procedures: Use the same procedure every time to minimize variability.

- Training: Ensure all personnel are trained in the testing procedures.

- Quality Control: Implement a quality control system to monitor and review test results.

- Environmental Control: Conduct tests in a controlled environment to reduce external influences.

By following these best practices, you can ensure accurate and reliable results in your specific gravity tests of cement. Always aim for precision and consistency in every test.

Frequently Asked Questions

How To Calculate Specific Gravity?

Calculate specific gravity by dividing the substance’s density by the density of water. Use the formula: Specific Gravity = Density of Substance / Density of Water.

How Do You Find The Specific Density Of Cement?

To find the specific density of cement, use a Le Chatelier flask or a pycnometer. Fill it with kerosene, add cement, and measure the displaced volume.

Why Don T We Use Water To Determine The Cement Specific Gravity?

Water can react with cement, leading to inaccurate specific gravity measurements. Use kerosene or non-reactive liquids instead.

How To Find Specific Gravity Of Cement Pdf?

Search for “specific gravity of cement PDF” on Google. Choose reputable sources like academic sites or engineering forums.

Conclusion

Determining the specific gravity of cement is vital for quality construction. Accurate measurements ensure strong, durable structures. Using precise tools and methods makes the process straightforward. Always follow standard procedures for reliable results. This ensures that your construction projects meet industry standards and maintain structural integrity.