Signs of TMT rebar failure include visible cracks, corrosion, and unusual bending or deformation. These indicators suggest that the structural integrity is compromised.

TMT (Thermo Mechanically Treated) rebars are essential for the strength and stability of concrete structures. They are designed to reinforce buildings, bridges, and roads, ensuring they can withstand various stresses and strains. Spotting the early signs of failure in these rebars is crucial for maintaining safety and preventing potential disasters.

Structural engineers and construction professionals must routinely inspect TMT rebars for signs of wear and tear. Timely detection of such issues allows for the necessary interventions to repair or replace the affected rebars, thereby preserving the longevity of the infrastructure. Knowing what to look for can save time, resources, and, most importantly, lives, making vigilance a key factor in construction and maintenance practices.

Introduction To Tmt Rebar Significance

TMT Rebar plays a key role in construction. Its strength and flexibility make buildings and bridges safe. Understanding signs of failure is crucial. This ensures structures stand strong over time.

Role In Construction

TMT Rebars, or Thermo-Mechanically Treated Rebars, are essential in modern construction. They provide the backbone for concrete structures. These rebars support buildings against natural forces like earthquakes and storms.

- Support: They hold the structure upright.

- Flexibility: They bend without breaking.

- Strength: They resist pressure and weight.

Importance Of Durability

Durability means how long something lasts. For TMT Rebars, it’s vital. Durable rebars save money and keep us safe.

- Long-lasting rebars reduce repair costs.

- They ensure buildings can withstand harsh conditions.

- Safety increases with the use of high-quality TMT Rebars.

| Quality | Benefit |

|---|---|

| High Strength | Supports more weight |

| Flexibility | Prevents breaks during natural disasters |

| Durability | Less need for repairs |

Strong buildings need strong TMT rebars. But sometimes, rebars can fail. Spotting these failures early is key. Let’s look at common TMT rebar failures.

Corrosion Indicators

Color changes on rebars often mean corrosion. Rust is the most obvious sign. It’s a red or brown color. Look for it on the rebar surface.

- Rust formation suggests water contact.

- Pitting shows deeper damage.

Corrosion weakens rebars. This leads to structural issues. It’s a serious problem.

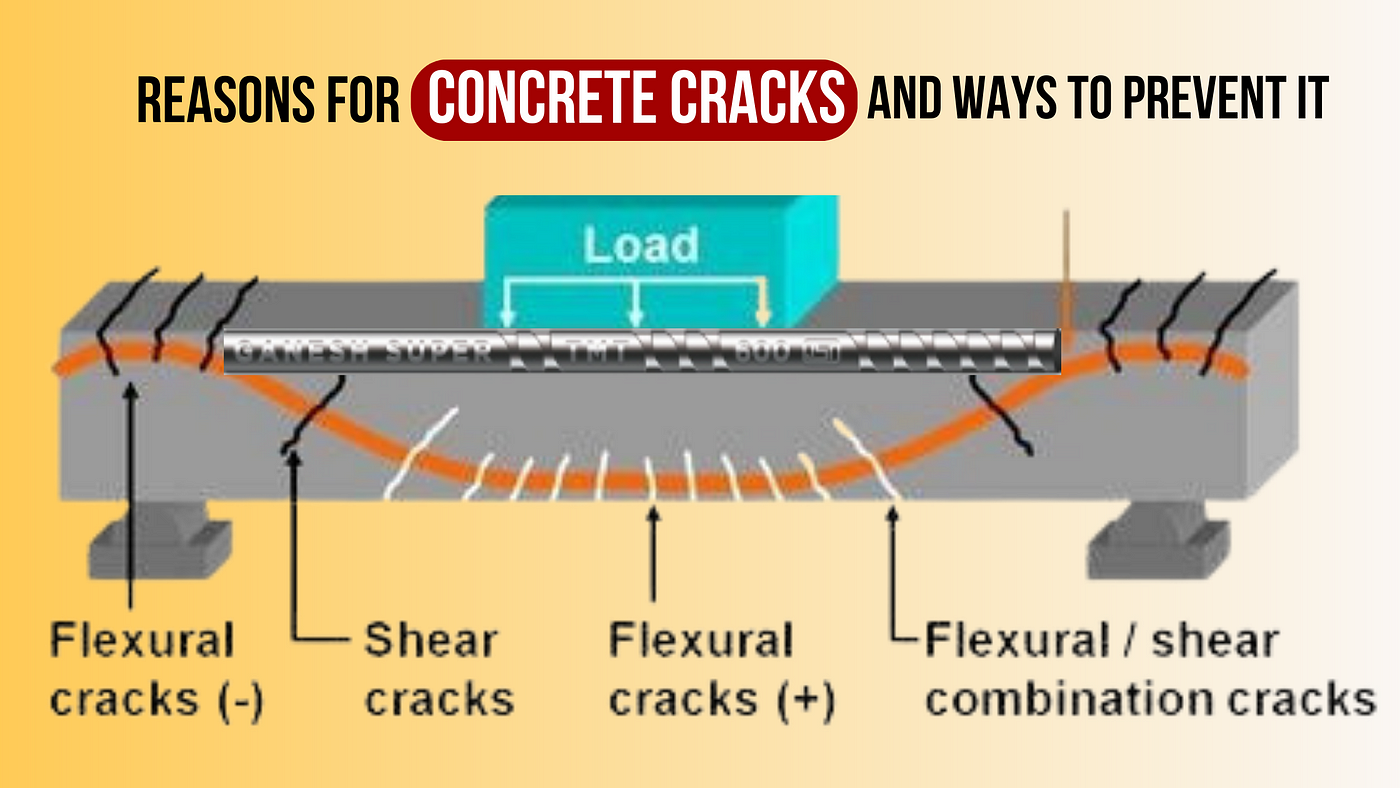

Surface Cracking

Cracks on concrete can mean rebar problems. They can be thin or wide. Check them closely.

| Crack Type | Significance |

|---|---|

| Thin cracks | Could be shrinkage |

| Wide cracks | Possible rebar expansion |

Surface cracks must be assessed. Rebars inside might be expanding. This is often due to rust buildup.

Mechanical Damage To TMT Rebars

Mechanical damage to TMT rebars can compromise a structure’s integrity. It’s vital to spot signs early.

Bending Issues

TMT rebars must bend correctly to ensure safety. Improper bending causes weak points. Look for:

- Sharp angles: Suggest improper handling.

- Cracks at bends: Indicate possible failure.

- Uneven surfaces: Show poor bending techniques.

Brittle Fractures

Brittle fractures signal severe damage. TMT rebars should be tough and ductile. Signs include:

- Snapped bars: Reflect critical damage.

- Irregular break patterns: Point to brittleness.

- No deformation before breaking: Rebars should bend first.

Credit: www.quora.com

Environmental Factors Affecting Tmt Rebars

The integrity of TMT rebars is crucial in construction. Yet, certain environmental factors can affect their longevity and performance. Let’s delve into these factors and their effects.

Exposure To Extreme Conditions

TMT rebars face stress under extreme weather. Such conditions include:

- High temperatures from fires or heatwaves.

- Freezing cold which can cause brittleness.

- UV radiation that weakens the outer layer.

Over time, these factors can lead to structural failings. Constant monitoring and maintenance are key to preventing this.

Chemical Reactions

Chemicals in the environment can react with TMT rebars. These reactions can cause:

| Chemical | Effect |

|---|---|

| Chlorides | Corrosion and strength loss |

| Carbonation | Reduction in pH, protective layer breakdown |

| Sulfates | Expansion and cracking |

Using protective coatings can shield rebars from harmful chemicals.

Visual Inspection Techniques

Regular checks keep buildings safe. Spotting rebar failure early saves lives. Construction experts use visual inspection. Let’s look at how they spot trouble.

Rust Formation

Rust on rebar is a warning sign. It weakens the metal. Inspectors look for orange or brown stains. These stains mean rust is present.

- Surface rust might be okay.

- Deep rust suggests serious damage.

Discoloration And Pitting

Rebar should look uniform. Color changes or spots can signal issues. Pitting, or small holes, can be a problem too.

| Sign | What It Means |

|---|---|

| Discoloration | Material decay or contamination. |

| Pitting | Possible loss of structural integrity. |

Credit: www.researchgate.net

Advanced Diagnostic Methods

Understanding the health of TMT rebar is crucial for any construction. Advanced Diagnostic Methods help us find problems early. This means we can fix issues before they get big. Let’s explore two powerful tools: Ultrasonic Testing and Radiography.

Ultrasonic Testing

Ultrasonic Testing uses sound waves to check rebar. It’s like how bats see in the dark. This method can find tiny cracks that we can’t see with our eyes. Here’s how it helps:

- Finds small flaws inside the rebar.

- Measures how thick the rebar is.

- Quick and safe for the person using it.

It’s great for checking big areas fast without cutting the rebar.

Radiography

Radiography takes pictures of the inside of rebar using X-rays. Think of it like a superhero power, seeing through metal to spot trouble. This method is super good for:

- Seeing inside complex parts.

- Finding hidden cracks and corrosion.

- Checking the quality of welds.

This method needs special safety steps because it uses X-rays. But, it gives us very clear pictures of problems.

Preventive Measures For TMT Rebar Longevity

Strong buildings need strong materials. TMT rebars ensure this strength. Yet, they can fail. Understanding how to keep them strong is key. This section guides you through the best practices to prevent TMT rebar failure.

Protective Coatings

Coatings guard rebars against rust. Anti-corrosive paints are a popular choice. They seal the rebar from moisture. Epoxy coatings offer a thicker shield. They bond well with concrete.

- Choose the right coating.

- Apply it correctly.

- Check regularly for damage.

Regular Maintenance

Maintenance spots issues early. It saves costs. It extends rebar life. Maintenance includes:

- Inspection for cracks and rust.

- Cleaning of exposed rebars.

- Repairing damaged coatings.

Professional teams can help. They use tools and techniques. They ensure rebars remain in top shape.

Case Studies: Lessons From Past Failures

Studying past failures gives insight into TMT rebar performance. These case studies highlight the importance of vigilance in construction and maintenance.

Infrastructure Collapses

Understanding structural failures helps prevent future incidents. Here are key examples:

- Bridge Failures: Poor rebar quality often leads to cracks, rust, and eventual collapse.

- Building Collapses: Inadequate rebar can’t support weight, resulting in tragic falls.

- Dams Breaking: Damaged rebars compromise stability, posing flood risks.

Lessons learned from these collapses have shaped building codes and inspection protocols.

Conclusion: Proactive Approach To TMT Rebar Care

A proactive approach to TMT rebar care is critical. It ensures the longevity and safety of a structure. Detecting issues early can save time and money.

Importance Of Early Detection

Early detection of TMT rebar failure is key. It helps prevent major structural issues. Regular inspections are a must. They help spot signs of corrosion or damage. This allows for timely repairs.

- Visual inspections can reveal rust and cracks.

- Non-destructive tests assess internal rebar conditions.

- Repair plans can be made before major damage occurs.

Ensuring Structural Integrity

Structural integrity depends on the quality of TMT rebar. Proper maintenance is essential. It ensures buildings stand strong.

- Check TMT rebars regularly.

- Follow maintenance protocols strictly.

- Address signs of wear immediately.

Skilled professionals should perform these tasks. They use the right tools and techniques. This maintains safety and durability.

Frequently Asked Questions

How Do I Check My Tmt Bar?

To check your TMT bar, observe its surface for uniform rib patterns, ensure the manufacturer’s mark is visible, bend the bar to test flexibility, check for corrosion resistance, and verify its weight matches the standard specifications.

What Is The Defect In Tmt Bar?

A defect in TMT bars can be surface cracks, inconsistent rib patterns, or improper chemical composition, impacting their strength and durability.

What Is The Life Of A Tmt Bar?

The lifespan of a TMT bar typically ranges from 40 to 50 years, depending on environmental conditions and maintenance practices.

What Is The Lifespan Of Steel Rebar?

The lifespan of steel rebar typically ranges from 50 to 100 years. Factors like environmental conditions and maintenance play a crucial role in its durability. Regular inspections can help extend its life.

Conclusion

Understanding the signs of TMT rebar failure is crucial for maintaining structural integrity. Spotting these indicators early can prevent potential hazards and ensure safety. Regular inspections and immediate action upon noticing any warning signs are key. Remember, the stability of your construction relies heavily on the health of its reinforcing bars.

Stay vigilant and proactive to safeguard your projects.