In the evolving landscape of Bangladesh’s cement industry, AKIJ Cement Company

Limited stands at the forefront, integrating cutting-edge technologies to enhance

production efficiency and sustainability.

Since its founding on November 3, 2002, AKIJ Cement has been committed to

producing high-quality cement in alignment with customer demands. As part of AKIJ

Resource, the company has set a standard for innovation by being the first in

Bangladesh to implement Vertical Roller Mill (VRM) technology. This adoption has

enabled AKIJ Cement to provide home builders with the highest quality cement,

surpassing conventional standards.

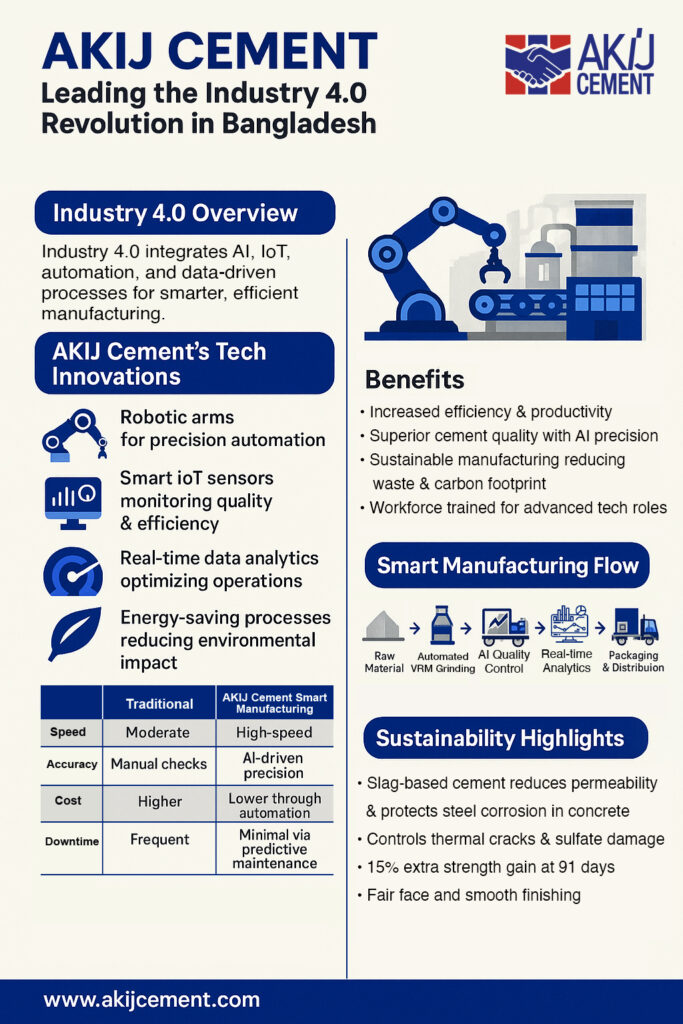

With Industry 4.0 technologies such as automation, artificial intelligence (AI), and

digital monitoring (CCR), AKIJ Cement is not just keeping pace with global trends but

actively shaping the future of cement manufacturing in the region.

How Smart Manufacturing is Transforming the Cement Sector

Smart manufacturing in the cement industry is not just about producing high-quality

products; it’s about achieving operational excellence, sustainability, and efficiency.

AKIJ Cement’s commitment to technological advancement has led to several

breakthroughs in this space:

The Latest Cement Grinding Technology

AKIJ Cement’s early adoption of Vertical Roller Mill (VRM) technology has redefined

cement production in Bangladesh. This technology allows the company to produce

ultrafine cement particles ranging from 2 to 50 microns, enhancing the strength and

durability of concrete. The use of VRM ensures that every batch of cement meets the

highest standards of quality and consistency.

Artificial Intelligence and Machine Learning

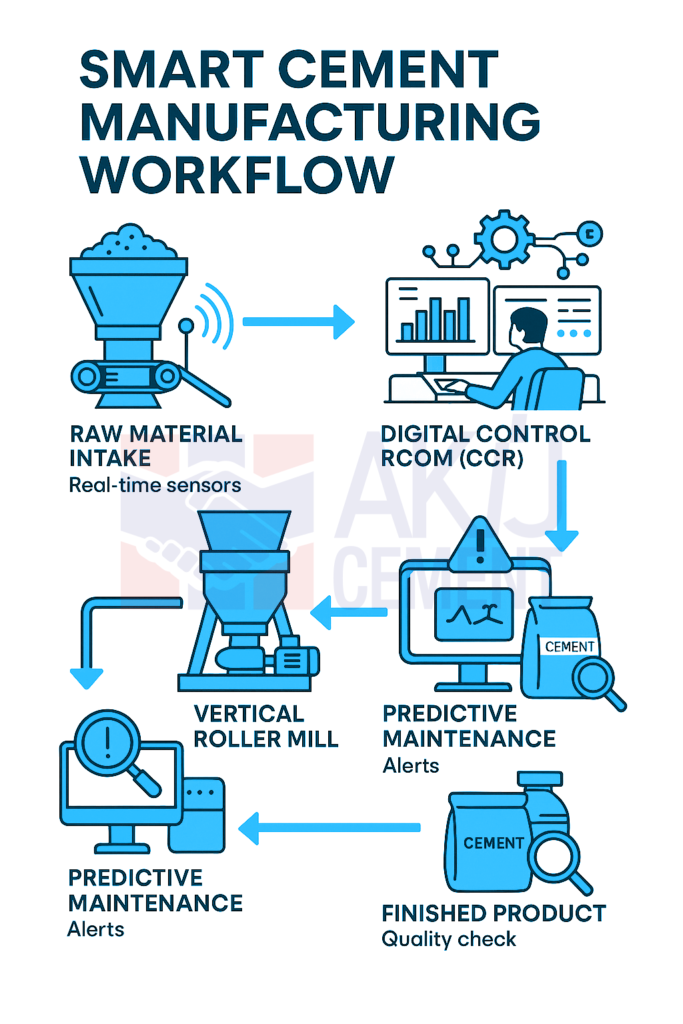

AI and ML play a crucial role in predictive maintenance, production quality monitoring,

and energy optimization. These technologies not only improve efficiency but also

ensure that AKIJ Cement consistently delivers high-quality products to meet the

growing demands of the construction sector in Bangladesh.

Key Technologies Driving Automation in Cement Manufacturing

Enterprise Resource Planning (ERP) Systems

The implementation of ERP systems has streamlined AKIJ Cement’s operations by

integrating various business processes—from raw material procurement to distribution.

This integration enhances operational visibility and enables the company to respond

quickly to market dynamics.

Robotic Process Automation (RPA)

AKIJ Cement utilizes RPA to automate routine tasks such as data entry and production

scheduling, reducing manual labor and increasing efficiency.

Advanced Analytics

By leveraging big data, AKIJ Cement derives actionable insights to optimize production

cycles, forecast demand, and support strategic decision-making.

Digital Control Systems

The fully digitized central control room at AKIJ Cement allows real-time monitoring of

production processes, enabling immediate adjustments to optimize efficiency and

maintain quality. This system strengthens the company’s ability to tightly control

production schedules and product specifications.

Real-Time Data and IoT in Cement Production Processes

AKIJ Cement has integrated Internet of Things (IoT) sensors throughout its production plants to gather real-time data on key parameters such as temperature, humidity, and equipment health. This data is continuously analyzed to optimize manufacturing processes, reduce energy consumption, and maintain the high standards expected by the company’s customers.

- Predictive Maintenance: IoT sensors monitor machinery to detect anomalies and predict maintenance needs, minimizing downtime and maximizing equipment lifespan.

- Energy Efficiency: Real-time data enables the company to optimize energy usage, leading to cost savings and a reduced environmental impact.

- Quality Assurance: Continuous monitoring ensures that the cement produced maintains consistent quality, reducing the risk of defects and ensuring the end product meets the demands of high-performance construction projects.

Benefits of Automated Cement Plants in Operational Efficiency

AKIJ Cement’s decision to automate its manufacturing processes has yielded significant benefits, particularly in terms of operational efficiency:

Reduced Human Error: Automation minimizes the chances of human error in the production process, ensuring more consistent product quality.

Enhanced Production Efficiency: Automated systems accelerate the production process and reduce downtime, enabling AKIJ Cement to consistently meet the growing demand for high-quality products amid Bangladesh’s infrastructure boom.

Improved Safety: Automation reduces the need for workers to interact with hazardous materials or machinery, thereby enhancing safety standards across the plant.

Benefits of Innovative Cement Techniques in Quality Assurance

AKIJ Cement is committed to sustainability, and its investment in smart manufacturing technologies reflects this dedication. One such example is the use of Blast Furnace Slag (BFS) in its cement production, which offers several consumer-friendly benefits:

- Reduced Permeability: Slag-based cement generates additional Calcium Silicate Hydrate (CSH) gel during the hydration process. This reduces water ingress in concrete, making it more durable and resistant to environmental stressors.

- Corrosion Resistance: The incorporation of Blast Furnace Slag helps prevent steel corrosion in concrete, thereby enhancing the longevity of structures.

- Thermal Crack Control: Slag cement lowers the risk of thermal cracking caused by the heat of hydration, ensuring better structural integrity over time.

- Sulphate Resistance: Slag cement exhibits high resistance to sulphate attacks, making it ideal for areas with elevated sulphate levels in soil or water.

- Enhanced Strength: The chemical composition of slag is similar to that of clinker. Its strength-gaining capability over time ensures at least 15% higher strength compared to conventional cement types.

Superior Finishing: Concrete made with Akij Cement is often smoother and lighter than traditional mixes. Its smooth, uniform appearance enhances the visual appeal of fair-faced concrete structures, bringing out their aesthetic beauty.

AKIJ Cement Leading the Industry 4.0 Revolution in Bangladesh

AKIJ Cement’s digital transformation serves as a model for other industries in Bangladesh, demonstrating how embracing Industry 4.0 technologies can unlock new opportunities for growth and innovation.

Government and Industry Collaboration in Smart Infrastructure

The Bangladesh government’s push for digital infrastructure has laid the foundation for AKIJ Cement’s technological advancements. Collaborative efforts between the public and private sectors are essential to driving innovation and accelerating economic growth.

Training and Upskilling the Workforce for Smart Manufacturing

Recognizing the importance of a skilled workforce, AKIJ Cement has invested in training programs to ensure its employees are well-equipped to operate and manage advanced manufacturing technologies. This investment in human capital is key to the company’s sustained success.

Challenges and Opportunities in Scaling Automation Across the Sector

While AKIJ Cement’s automated systems have already created a competitive edge, challenges such as high implementation costs and the need for specialized skills persist. However, these challenges also present opportunities for sector-wide growth and industry leadership.

Conclusion

AKIJ Cement Company Limited’s integration of smart manufacturing and automation

processes have set a new benchmark in Bangladesh’s cement industry. With over two

decades of experience, AKIJ Cement has demonstrated its commitment to producing

high-quality products by leveraging innovative technologies such as VRM, AI, and

digital control systems. As the company continues to evolve, its leadership in

sustainability and smart manufacturing will ensure it remains a pioneer in the industry,

driving the future of cement production in Bangladesh.