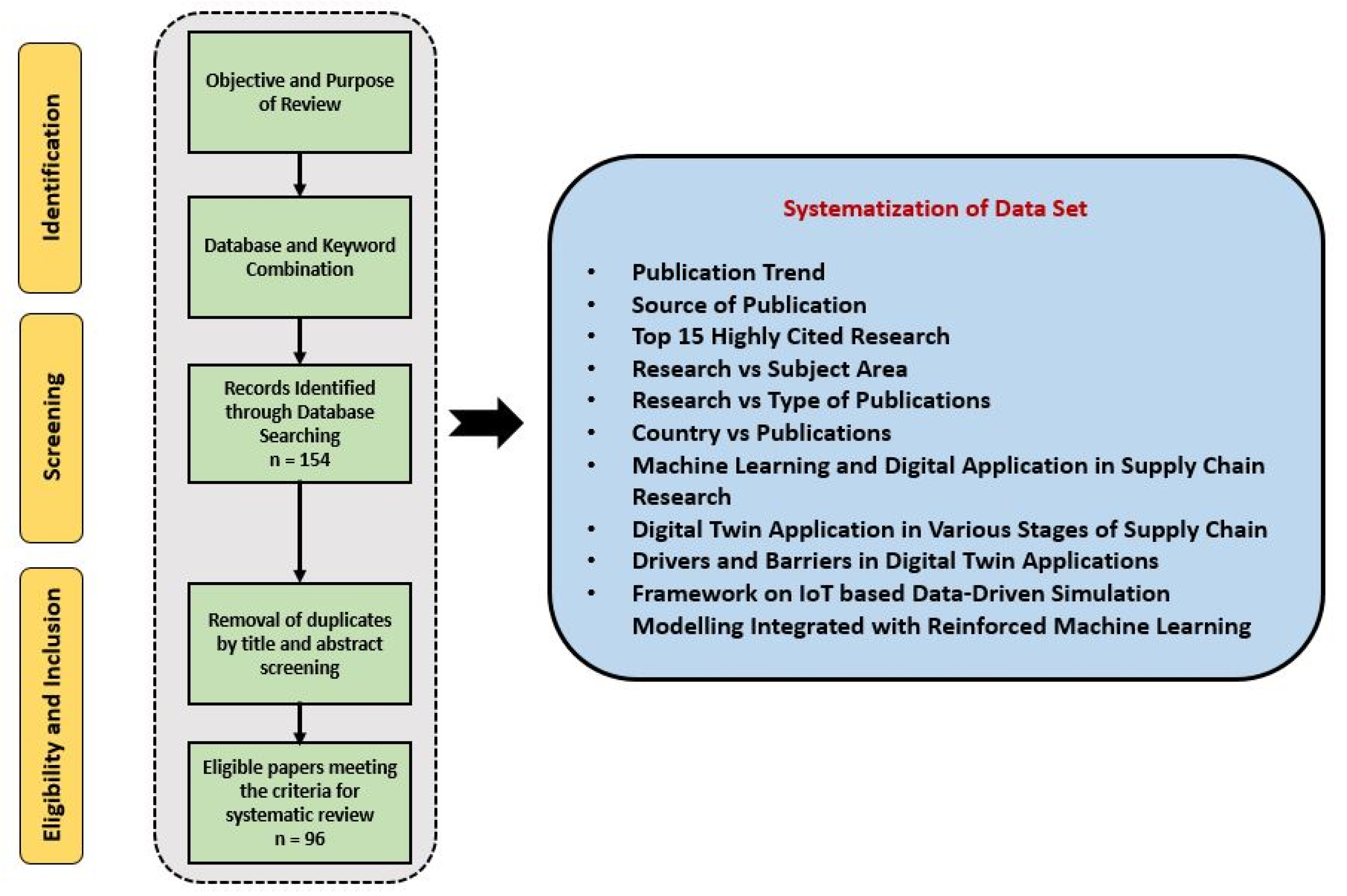

Digitalization is changing the world. It is transforming industries. One such industry is the cement industry. In Bangladesh, digitalization is making a big impact. It is improving cement supply chains in many ways.

Understanding Cement Supply Chains

A supply chain is a network. It involves the production and delivery of products. In the cement industry, the supply chain includes several steps. These steps include:

- Raw material extraction

- Production

- Distribution

- Delivery to customers

Each step is important. Each step must work smoothly. If one step fails, the whole chain suffers.

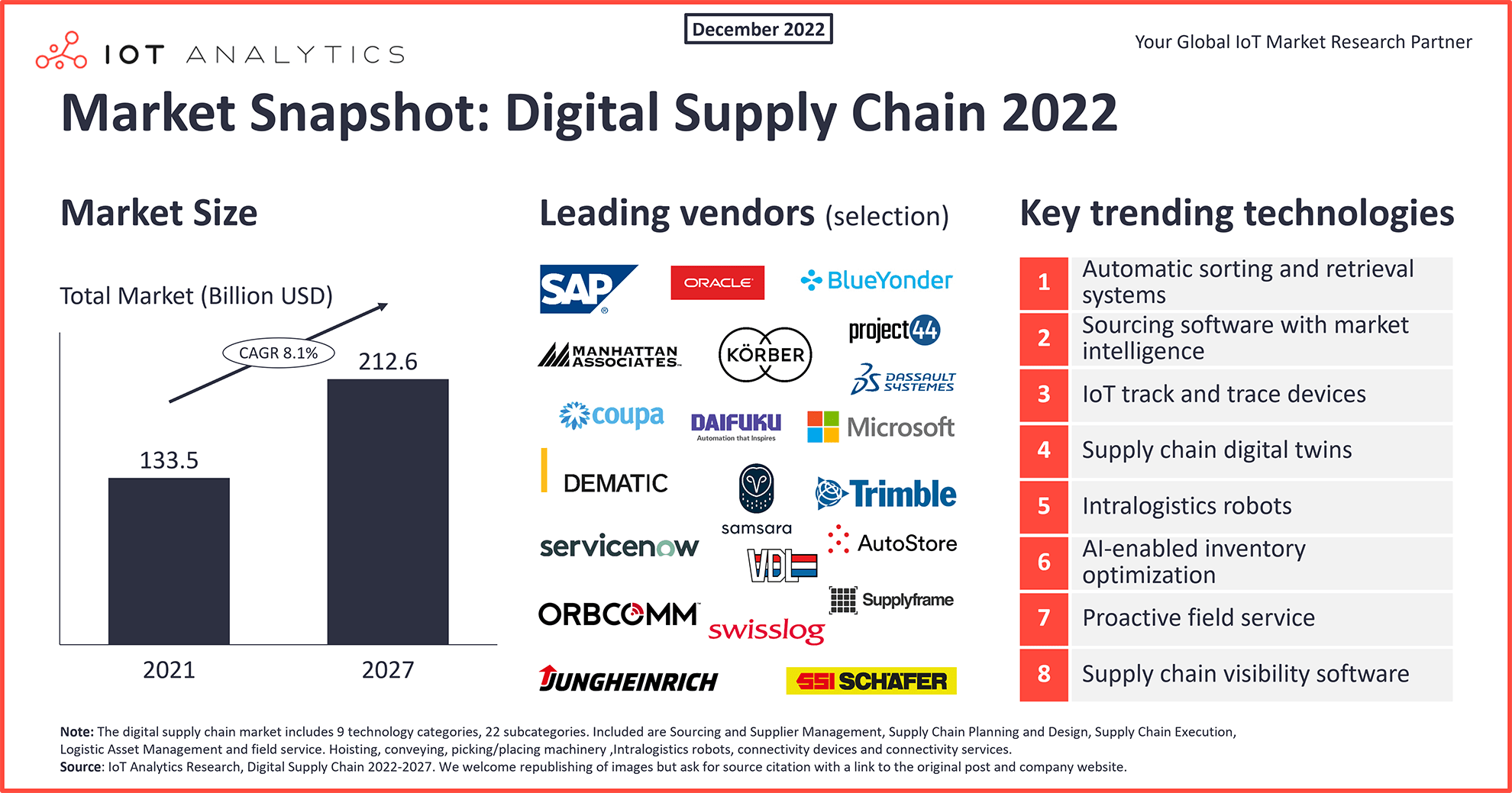

Credit: iot-analytics.com

What is Digitalization?

Digitalization means using digital technology. It helps to improve processes. It makes them faster and more efficient. In the cement industry, digitalization can help in many ways. It can improve the supply chain. It can make it more efficient and cost-effective.

Benefits of Digitalization in Cement Supply Chains

Digitalization offers many benefits. Here are some key benefits for cement supply chains in Bangladesh:

1. Improved Efficiency

Digital tools can automate tasks. This reduces human error. It speeds up processes. It makes the supply chain more efficient.

2. Better Inventory Management

Digital tools can track inventory in real-time. This helps companies know when to reorder. It prevents stockouts and overstocking.

3. Enhanced Communication

Digital tools improve communication. They allow real-time updates. This helps all parts of the supply chain stay informed.

4. Cost Savings

Digitalization reduces costs. It cuts down on waste. It improves resource management. It makes the supply chain more cost-effective.

5. Better Decision Making

Digital tools provide data. This data helps in making informed decisions. It allows companies to respond quickly to changes.

Challenges of Digitalization in Cement Supply Chains

While digitalization offers many benefits, it also comes with challenges. Here are some challenges faced by the cement industry in Bangladesh:

1. High Initial Costs

Implementing digital tools can be expensive. It requires investment in technology and training.

2. Resistance To Change

Some employees may resist change. They may be used to traditional methods. Training and education are necessary to overcome this.

3. Cybersecurity Risks

Digital systems are vulnerable to cyber attacks. Companies must invest in cybersecurity measures to protect data.

4. Lack Of Skilled Workforce

Digitalization requires skilled workers. There may be a shortage of such workers in Bangladesh. Training programs are necessary to build skills.

Credit: proventainternational.com

Future of Digital Supply Chains in the Cement Industry

The future of digital supply chains looks bright. Here are some trends to watch:

1. Internet Of Things (iot)

IoT devices can collect data in real-time. They can monitor equipment and processes. This helps in predictive maintenance and improves efficiency.

2. Artificial Intelligence (ai)

AI can analyze data. It can provide insights. It can help in making better decisions.

3. Blockchain Technology

Blockchain can improve transparency. It can track the movement of goods. It ensures the authenticity of products.

4. Cloud Computing

Cloud computing allows for real-time data access. It improves collaboration. It makes data storage and retrieval easier.

Case Study: Digitalization in Cement Supply Chains in Bangladesh

Let’s look at a case study. A leading cement company in Bangladesh decided to digitalize its supply chain. The company faced many challenges. But the results were impressive.

| Challenges | Solutions | Results |

|---|---|---|

| High Initial Costs | Invested in phased manner | Reduced overall expenses |

| Resistance to Change | Conducted training programs | Improved employee acceptance |

| Cybersecurity Risks | Implemented strong security measures | Protected data from breaches |

| Lack of Skilled Workforce | Launched skill development programs | Built a skilled workforce |

The company saw many benefits. Efficiency improved. Costs reduced. Inventory management became better. Communication enhanced. Decision-making improved. The overall supply chain became more robust.

Frequently Asked Questions

What Is Digitalization In Cement Supply Chains?

Digitalization uses technology to streamline and optimize cement supply chain operations.

How Does Digitalization Improve Efficiency?

It reduces manual errors, speeds up processes, and enhances data accuracy.

Why Is Digitalization Important For Bangladesh?

It helps meet growing construction demands efficiently and sustainably.

What Technologies Are Used In Digitalization?

Technologies include IoT, AI, and blockchain for better tracking and management.

Conclusion

Digitalization is transforming cement supply chains in Bangladesh. It offers many benefits. It improves efficiency. It reduces costs. It enhances communication. It improves decision-making. However, there are challenges. High initial costs, resistance to change, cybersecurity risks, and lack of skilled workforce are some. But with the right approach, these challenges can be overcome. The future of digital supply chains looks promising. Technologies like IoT, AI, blockchain, and cloud computing will play a key role. Companies must embrace digitalization. It is the way forward.

If you want to stay competitive, digitalize your supply chain. It will make your operations smoother. It will help you meet customer demands better. Embrace digitalization today. It is the future of the cement industry in Bangladesh.