High-speed rail construction in Bangladesh is a big project. Cement plays a crucial role in it. In this article, we will explore why cement is so important for building rail tracks. Cement is a fundamental component in the construction of rail tracks, providing the necessary strength and stability to support the weight of the trains. As Bangladesh continues to invest in high-speed rail infrastructure, cement will also be essential in supporting the innovative urban development trends in Bangladesh. The use of high-quality cement in the construction of rail tracks will contribute to the overall modernization and efficiency of the country’s transportation network.

Why Is Cement Important?

Cement is a key material in construction. It is used to make concrete. Concrete is strong and durable. It can bear heavy loads and last for many years.

The Basics of Cement

Cement is made from limestone, clay, and other materials. These materials are heated together at high temperatures. The result is a fine powder called cement.

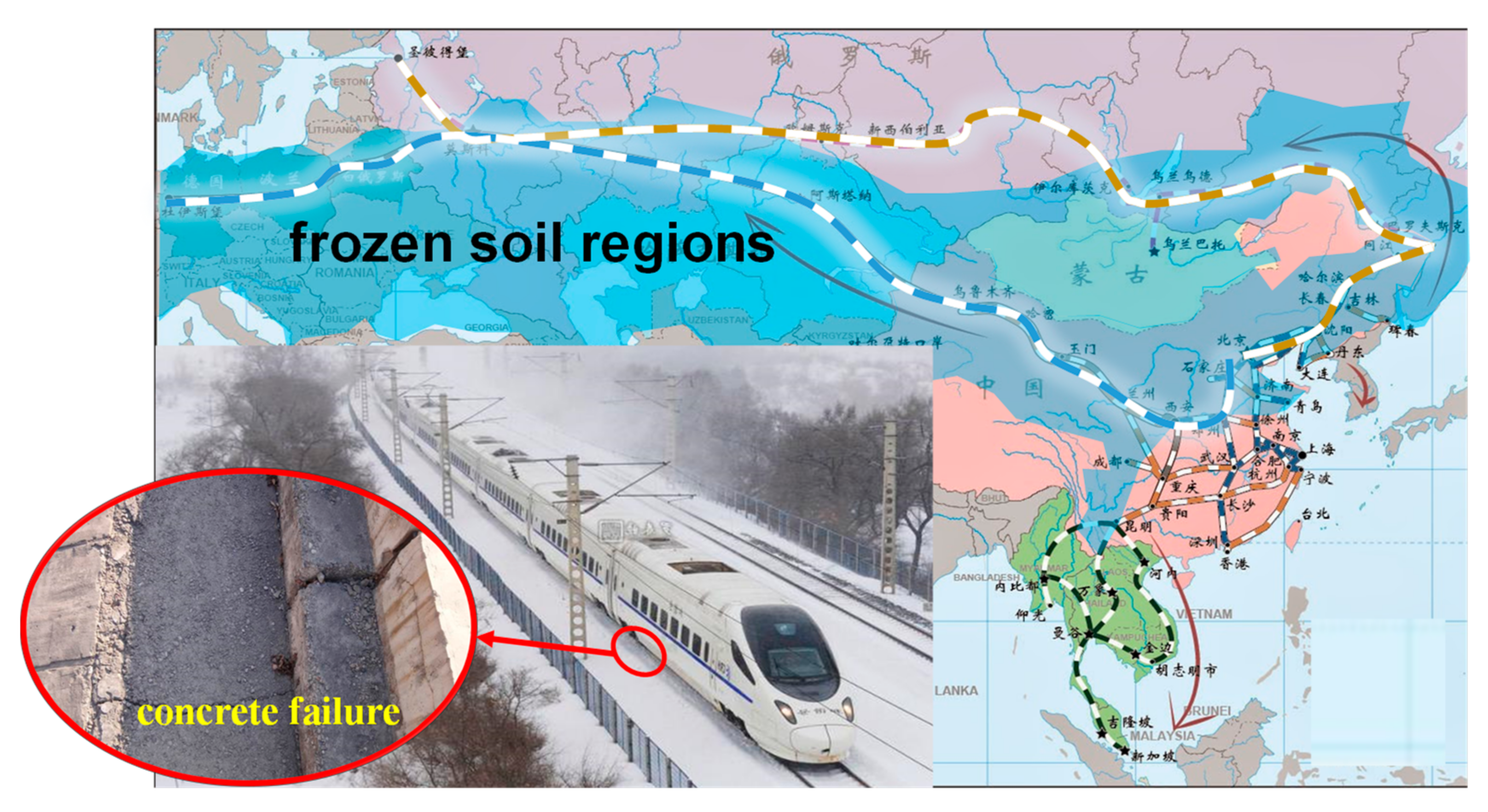

Credit: www.mdpi.com

Types of Cement Used in High-Speed Rail Construction

Different types of cement are used in high-speed rail construction. Here are some common types:

- Ordinary Portland Cement (OPC): This is the most common type. It is used for general construction.

- Rapid Hardening Cement: This type hardens quickly. It is used when fast construction is needed.

- High-Strength Cement: This type is very strong. It is used for heavy-duty structures.

Steps in High-Speed Rail Construction

Building high-speed rail tracks involves several steps. Cement is used in many of these steps. Let’s look at each step:

1. Site Preparation

The first step is to prepare the site. This involves clearing the land and leveling it. Cement is used to create a stable base for the tracks.

2. Laying The Foundation

The next step is laying the foundation. This is a crucial step. A strong foundation ensures the tracks remain stable. Cement is mixed with gravel and sand to make concrete. This concrete is poured into molds to form the foundation.

3. Building The Track Bed

After the foundation is ready, the track bed is built. The track bed supports the rails and ties. Cement is used to create a solid track bed. This helps in reducing vibrations and noise.

4. Installing The Rails

The rails are then installed on the track bed. Special clips and fasteners are used to hold the rails in place. Cement is used to secure these fasteners. This ensures the rails do not move.

5. Adding The Ballast

Finally, ballast is added. Ballast is crushed stone or gravel. It helps to distribute the load and keep the tracks in place. Cement is sometimes mixed with the ballast to make it more stable.

Benefits of Using Cement in Rail Construction

Using cement in high-speed rail construction has many benefits. Here are some of them:

- Strength: Cement makes the tracks strong. This is important for high-speed trains.

- Durability: Tracks made with cement last a long time. They can withstand harsh weather conditions.

- Stability: Cement helps to keep the tracks stable. This reduces the chances of derailments.

- Cost-Effective: Cement is a cost-effective material. It provides good value for money.

Challenges in Using Cement

There are some challenges in using cement. Here are a few:

- Setting Time: Cement takes time to set. This can slow down construction.

- Temperature Sensitivity: Cement can be sensitive to temperature changes. This can affect its strength.

- Environmental Impact: Cement production can have a negative impact on the environment. It produces carbon dioxide, which contributes to global warming.

Solutions to Overcome Challenges

There are solutions to overcome these challenges. Here are some ways to address them:

- Use Additives: Additives can be mixed with cement to speed up the setting time.

- Temperature Control: Construction can be planned to avoid extreme temperatures.

- Eco-Friendly Cement: New types of eco-friendly cement are being developed. These produce less carbon dioxide.

The Future of High-Speed Rail in Bangladesh

The future of high-speed rail in Bangladesh looks bright. The government is investing in infrastructure. New rail projects are being planned. Cement will continue to play a key role in these projects.

Credit: new.abb.com

Frequently Asked Questions

What Is The Role Of Cement In Rail Construction?

Cement provides stability and strength to railway tracks, ensuring a smooth and safe high-speed train journey.

Why Is Cement Important For High-speed Rails?

Cement ensures durability and longevity of the rail infrastructure, reducing maintenance costs and enhancing safety.

How Does Cement Improve Rail Safety?

Cement stabilizes the tracks and foundations, preventing shifts and ensuring secure, high-speed travel.

What Type Of Cement Is Used In Railways?

Specialized high-strength cement is often used to meet the rigorous demands of high-speed rail construction.

Conclusion

Cement is an essential material in high-speed rail construction. It provides strength, durability, and stability. Despite some challenges, solutions are available. The future of high-speed rail in Bangladesh is promising. Cement will be a key part of this future.